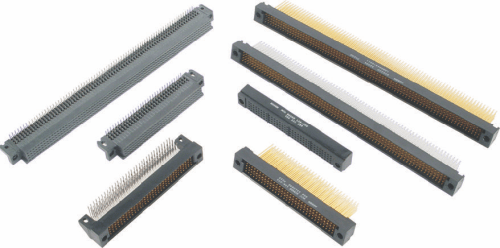

856-SERIES

- Characteristics

- Products

Characteristics

- 2.54 X 2.54 grid spacing

- 4 rows with single bay

- Solder I Press fit pins

- 3 Amp rating per contact

- 64 position octagon keying

- Gold plating in mating and tin lead in tail sections of the contacts

- Closed contact entry system prevents damage of contacts in female connector

- Moulded mounting ears provide added strength and rigidity in male right angle connector

- Back shrouds are available

- Press fit/ compliant pins with eye of the needle design

Technical Data:

Contact spacing

Polaization

Operating Current

Dielectric withstand voltage

Isulation Resistance

Contact resistance

Insulation material

Contact material

Operating temprature

Contact finish

Insertion force

Withdrawal force

Contact retention

2.54 mm.

Connector space

3 Amps

900V rms. at sea level

5000 Mohms min.

15 mohms max. initial

20 mohms max. final

Flame retardant thermoplastic UL94V-O

Male – Copper alloy

Female – Copper alloy

-65°C to + 105°C

Contact zone – gold

Termination zone:

Male – Tin lead or gold

Female – Tin lead

42.53 gms. max. average per contact

14.18 gms. min. per contact

1.36 kg. max.

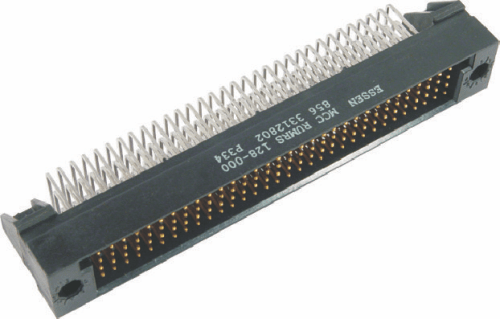

FEMALE, RIGHT ANGLED SOLDER (Four Row)

No. of Contacts

- 128

- 128

- 300

- 300

- 320

- 320

Contact arrangement

- 128 a, b,c,d

- 128 a, b, c,d

- 300 a,b,c,d

- 300 a,b,c,d

- 320 a,b,c,d

- 320 a,b,c,d

Termination F ± 0.5

- 3.05 mm.

- 4.57mm.

- 3.05 mm.

- 4.57mm.

- 3.05 mm.

- 4.57mm.

Ordering code

- 85633128 ( ) S331

- 85633128 ( ) S332

- 85634300 ( ) S341

- 85634300 ( ) S342

- 85635320 ( ) S351

- 85635320 ( ) S352

Add Following at ( ) in the Ordering Code above for contact finish required.

( ) Class 1- 01

Class 2- 02

Class 3- 03

Note : Please consult factory for other contact arrangement and contact finish.

No. of Contacts

- 128

- 300

- 320

Contact arrangement

- 128 a, b,c,d

- 300 a,b,c,d

- 320 a,b,c,d

Termination F ± 0.5

- 4.57mm.

- 4.57mm.

- 4.57mm.

Ordering code

- 85633128 ( ) P334

- 85634300 ( ) P344

- 85635320 ( ) P354

Add Following at ( ) in the Ordering Code above for contact finish required.

( ) Class 1- 01

Class 2- 02

Class 3- 03

Note : Please consult factory for other contact arrangement and contact finish.

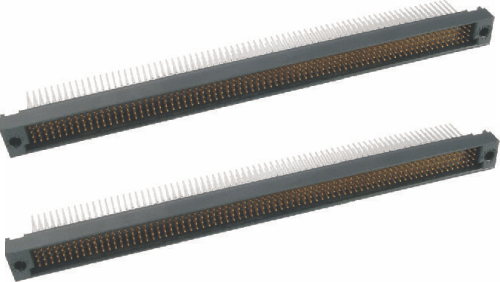

MALE, STRAIGHT DIP SOLDER ( Four row)

No. of Contacts

- 128

- 128

- 300

- 300

- 320

- 320

Contact arrangement

- 128 a, b,c,d

- 128 a, b,c,d

- 300 a,b,c,d

- 300 a,b,c,d

- 320 a,b,c,d

- 320 a,b,c,d

Termination F ± 0.5

- 4.50 mm.

- 6.35 mm.

- 4.50 mm.

- 6.35 mm.

- 4.50 mm.

- 6.35 mm.

Ordering code

- 85633128 ( ) P336

- 85633128 ( ) P337

- 85634300 ( ) P346

- 85634300 ( ) P347

- 85635320 ( ) P356

- 85635320 ( ) P357

Add Following at ( ) in the Ordering Code above for contact finish required.

( ) Class 1- 01

Class 2- 02

Class 3- 03

Note : Please consult factory for other contact arrangement and contact finish.

MALE, STRAIGHT WIRE WRAP (Four row)

No. of Contacts

- 128

- 128

- 128

- 300

- 300

- 300

- 320

- 320

- 320

Contact arrangement

- 128 a, b,c,d

- 128 a, b,c,d

- 128 a, b,c,d

- 300 a,b,c,d

- 300 a,b,c,d

- 300 a,b,c,d

- 320 a,b,c,d

- 320 a,b,c,d

- 320 a,b,c,d

Termination F ± 0.5

- 13.54 mm.

- 18.62 mm.

- 15.10 mm.

- 13.54 mm.

- 18.62 mm.

- 15.10 mm.

- 13.54 mm.

- 18.62 mm.

- 15.10 mm.

Ordering code

- 856 33128 ( ) P338

- 856 33128 ( ) P339

- 856 33128 ( ) P3310

- 856 34300 ( ) P348

- 856 34300 ( ) P349

- 856 34300 ( ) P3410

- 856 35320 ( ) P358

- 856 35320 ( ) P359

- 856 35320 ( ) P3510

Add Following at ( ) in the Ordering Code above for contact finish required.

( ) Class 1- 01

Class 2- 02

Class 3- 03

Note : Please consult factory for other contact arrangement and contact finish.

MALE,PRESS FIT, STRAIGHT WIRE WRAP (Four row)

No. of Contacts

- 128

- 128

- 128

- 300

- 300

- 300

- 320

- 320

- 320

Contact arrangement

- 128 a, b,c,d

- 128 a, b,c,d

- 128 a, b,c,d

- 300 a,b,c,d

- 300 a,b,c,d

- 300 a,b,c,d

- 320 a,b,c,d

- 320 a,b,c,d

- 320 a,b,c,d

Termination F ± 0.5

- 13.54 mm.

- 18.62 mm.

- 15.10 mm.

- 13.54 mm.

- 18.62 mm.

- 15.10 mm.

- 13.54 mm.

- 18.62 mm.

- 15.10 mm.

Ordering code

- 856 33P128 ( ) P338

- 856 33P128 ( ) P339

- 856 33P128 ( ) P3310

- 856 34P300 ( ) P348

- 856 34P300 ( ) P349

- 856 34P300 ( ) P3410

- 856 35P320 ( ) P358

- 856 35P320 ( ) P359

- 856 35P320 ( ) P3510

Add Following at ( ) in the Ordering Code above for contact finish required.

( ) Class 1- 01

Class 2- 02

Class 3- 03

Note : Please consult factory for other contact arrangement and contact finish.

BACK SHROUD

No. of Contacts

- 128

- 300

- 320

- 320

Ordering Code

- 85633128P

- 85634300P

- 85635320P

- 85635320PB

Ordering Code

- ————

- ————

- ————

- With barriers

Add Following at ( ) in the Ordering Code above for contact finish required.

( ) Class 1- 01

Class 2- 02

Class 3- 03

Note : Please consult factory for other contact arrangement and contact finish.

Ordering Code

Series

- 856

Form

- 33

- 128 – 33

- 300 – 34

- 320 – 35

Contact Style

- P

Solder – omitted

No. of contacts

- 120

- 128

- 300

- 320

Contact finish

- 02

- Class 1 – 01

- Class 2 – 02

- Class 3 – 03

Type

- P

- Male -P

- Female – S

Contact arrangement

- 33

- 128 a,b,c,d row (2.54 mm.)- 33

- 300 a,b,c,d row (2.54 mm.)- 34

- 320 a,b,c,d row (2.54 mm.)-35

Termination

- 1

- Female right angled solder pin

- 3.05mm. -1

- 4.57mm. -2

- +0.3

- 3.70mm.-0 -5

- Male right angled solder pin

- 4.57mm. -4

- Male Straight solder pin

- 4.50mm. -6

- 6.35mm. -7

- Male Wire Wrap

- 13.54mm. -8

- 18.62mm. -9

- 15.10mm. -10

Note:

- Add suffix ‘G’ for fully gold plated wire wrap

- Connectors with advanced contacts are available on

- Please consult factory for special requirements and for contact plating