In the high-stakes world of industrial automation, reliability isn’t just a feature it’s the foundation of safety and efficiency. A single loose connection can halt an entire production line. This is where the humble relay socket becomes a critical player. It acts as the vital interface between your control relays and the electrical circuit.

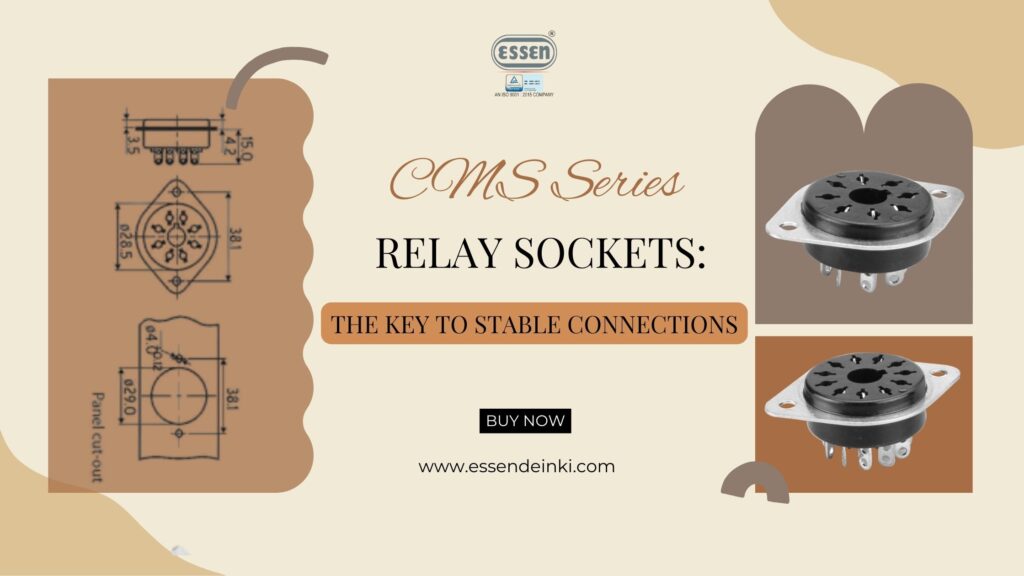

The CMS Series Relay Sockets from Essen Deinki are engineered specifically to bridge this gap with security and stability. Whether you are building a new control panel or upgrading legacy equipment, understanding the role of high-quality sockets is essential for long-term performance.

This guide explores why the CMS Series stands out, how it handles harsh industrial environments, and why it is the preferred choice for engineers prioritizing durability.

Why Choose CMS Series Relay Sockets?

When selecting components for chassis mounting, you need materials that can withstand heat and stress. The CMS Series distinguishes itself through robust construction and thoughtful design.

superior Material Construction

Unlike standard consumer-grade sockets that use thermoplastics, the CMS Series is crafted from high-quality Bakelite. This material choice offers distinct advantages:

- Heat Resistance: Bakelite maintains structural integrity at high temperatures where other plastics might warp or melt.

- Durability: It provides a rigid, strong base that resists mechanical stress.

- Professional Finish: The black finish isn’t just aesthetic; it signifies a heavy-duty component designed for industrial use.

Permanent Solder Terminals

Vibration is the enemy of electrical connections. In environments with motors, pumps, or heavy machinery, screw terminals can sometimes loosen over time. The CMS Series features solder terminals, which allow for a permanent, low-resistance connection. This design ensures that once a wire is connected, it stays connected, regardless of movement or vibration.

Technical Specifications at a Glance

Engineers need precise data to ensure compatibility. The CMS Series is built to handle significant power while maintaining safety standards.

Configuration Options:

- CMS 08: 8-Pin Relay Socket

- CMS 11: 11-Pin Relay Socket

Performance Ratings:

- Electrical Rating: 10A AC/DC at 240V RMS

- Dielectric Strength: 1500V AC RMS for 1 minute

- Insulation Resistance: Minimum 1000 MΩ at 500V DC

These specifications make the CMS Series versatile enough for both sensitive control circuits and more demanding power switching applications.

Built for Harsh Industrial Conditions

Industrial environments are rarely forgiving. They involve extreme temperature fluctuations, electrical noise, and constant mechanical stress. A standard socket might fail under these conditions, but the CMS Series is built to endure.

Extreme Temperature Tolerance

With an operating temperature range of -45°C to +120°C, these sockets perform reliably in freezing cold storage units and sweltering foundry floors alike.

International Safety Compliance

Safety is non-negotiable. The CMS Series complies with rigorous international standards, including EN 60947-5-1 and IEC 947-5-1. This compliance ensures that when you specify these sockets, you are meeting global benchmarks for safety and performance consistency.

Installation and Maintenance Made Easy

Time is money in industrial settings. The CMS Series is designed to minimize installation time and simplify future maintenance.

- Flexible Mounting: The sockets support both front and rear mounting using two standard M4 screws. This flexibility allows for seamless integration into various chassis designs and control panels.

- Standardized Dimensions: With mounting centers set at 38.1 mm, they fit easily into existing layouts without the need for drilling new holes or modifying panels.

- Quick Relay Replacement: One of the biggest benefits of using a high-quality socket is maintenance speed. If a relay fails, you can replace it instantly without disturbing the wiring. This “plug-and-play” capability significantly reduces downtime.

FAQ: Common Questions About Relay Sockets

Q.1 What is the difference between chassis mount and DIN rail mount sockets?

Ans: Chassis mount sockets, like the CMS Series, are screwed directly onto a panel or frame. This offers a very secure, low-profile installation ideal for permanent setups or environments with high vibration. DIN rail sockets clip onto a standardized rail for quick, modular installation but may not offer the same rigidity in high-vibration settings.

Q.2 Why use Bakelite for relay sockets?

Ans: Bakelite is a thermosetting phenol formaldehyde resin. It is chosen for electrical applications because it is an excellent insulator, does not melt or burn easily, and is resistant to chemical corrosion. This makes it superior to standard plastics for heavy-duty industrial components.

Q.3 Can I use the CMS Series for both AC and DC applications?

Ans: Yes, the CMS Series is rated for 10A at 240V RMS for both AC and DC currents, making it highly versatile for various control systems.

Q.4 How do solder terminals improve reliability?

Ans: Solder terminals create a metallurgical bond between the wire and the socket. Unlike screw terminals, which rely on mechanical pressure, soldered connections are impervious to loosening caused by thermal expansion/contraction or mechanical vibration.

Final Thoughts: Invest in Connection Stability

If you are looking for reliable, industry-compliant relay sockets, the CMS Series from Essen Deinki is a smart investment. By combining heat-resistant Bakelite construction with secure solder terminals, these sockets eliminate common failure points in automation systems.

Don’t let a small component cause a big problem. Choose the CMS Series for stability, safety, and peace of mind.

Ready to upgrade your control panels?

For detailed technical drawings and to browse the full catalog, visit the CMS Series Product Page.