D-Sub Connectors

Reliable D-Sub Connectors for Seamless Connectivity

Discover precision-crafted D-Sub Connectors that ensure durability, safety, and excellent electrical performance for your critical applications.

Engineered for Performance

M Series D-Sub Connectors

- Available in 5 shell sizes (E, A, B, C, D) with 9 to 50 contact configurations.

- Flame-retardant thermoplastic insulators (UL94V-O) for added safety.

- Trapezoidal shape ensures foolproof polarization.

- Perfect for data processing, telecom, and instrumentation industries.

Panel Cutouts

No. of contacts

- 09

- 15

- 25

- 37

- 50

Types of mounting

Rigid

Rigid

Rigid

Rigid

Rigid

Mounting Method

Front

Rear

Front

Rear

Front

Rear

Front

Rear

Front

Rear

A±0.2

22.2

20.5

30.5

28.8

44.3

12.3

60.7

59.1

58.3

56.3

B±0.2

11.1

10.2

13.3

14.4

22.1

21.3

30.4

29.5

29.2

28.2

C±0.2

25.0

25.0

33.3

33.3

47.0

47.0

63.5

63.5

61.1

61.1

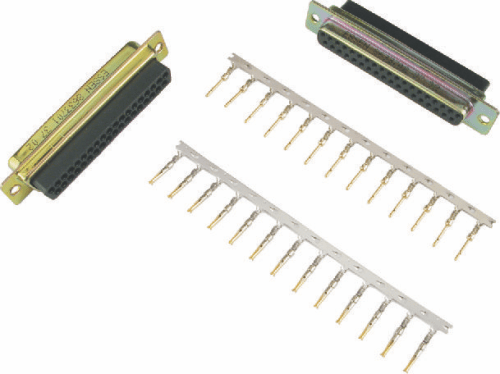

863 Series D-Sub Connectors

- Crimp-style contacts for effortless insertion and removal.

- Five shell sizes and configurations for tailored compatibility.

- Reliable support for conductor insulation after crimping.

- Ideal for compact designs requiring high signal integrity.

MALE CONNECTORS

No. of contacts

- 09

- 15

- 25

- 37

- 50

Ordering code

- 8630901

- 8631501

- 8632501

- 8633701

- 8635001

IDL Series D-Sub Connectors

- Built for robust connections with copper alloy contacts and flame-retardant thermoplastic insulators.

- Withstands dielectric strength up to 1000V and operates in temperatures from -50°C to +105°C.

- Suitable for ribbon cable terminations and high-speed signal routing.

MALE CONNECTORS

No. of contacts

- 09

- 15

- 25

- 37

With strain relief

- IDL09 PR( )

- IDL 15 PR( )

- IDL25 PR( )

- IDL37 PR( )

Without strain relief

- IDL09 PN ( )

- IDL 15 PN ( )

- IDL25 PN ( )

- IDL37 PN ( )

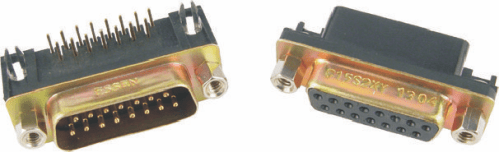

C Series D-Sub Connectors (8.1 mm Footprint)

- Durable steel shells with zinc, cadmium, or tin plating options.

- Designed to handle 5A current rating and 1000V dielectric strength.

- Low contact resistance, reliable insulation, and wide operating temperature range.

MALE CONNECTOR (PC right angle)

No. of contacts

- 09

- 15

- 25

- 37

Ordering code

- C09 P( )XY

- C15P ( )XY

- C25P ( )XY

- C37 P ( ) XY

Why Choose Essen Deinki D-Sub Connectors?

- Precision-engineered for reliability in harsh environments.

- Flame-retardant materials (UL94V-O) ensure safety and longevity.

- Trusted across industries like electronics, telecom, and automation.

- Full range of customization options to meet your specific needs.

Frequently Asked Questions

D-Sub Connectors are widely used in industrial automation, telecom systems, control panels, and PCB applications for reliable signal and power transmission. Their robust metal shell design ensures secure connections and protection against electromagnetic interference, making them ideal for both commercial and industrial environments.

Yes, D-Sub Connectors are available in various configurations designed to handle different current and voltage ratings. High-power variants are suitable for industrial equipment, automation systems, and communication devices where stable electrical performance is required.

There are several types of D-Sub Connectors, including standard density, high density, and mixed layout connectors. They are available in different pin counts and mounting styles such as PCB mount, panel mount, and cable mount to meet diverse application needs.

Yes, customized D-Sub Connectors can be manufactured with specific pin layouts, contact plating options, mounting styles, and shielding requirements. Custom configurations ensure compatibility with specialized industrial, telecom, or embedded system applications.

High-quality D-Sub Connectors are typically made with metal shells for shielding, gold-plated contacts for improved conductivity, and high-grade insulating materials for long-term durability. These materials enhance corrosion resistance, signal integrity, and overall connector lifespan.