When it comes to building reliable industrial automation systems, every component matters. From the largest machinery to the smallest electrical connector, each part plays a vital role in ensuring smooth operation. Among these components, industrial relay sockets often go unnoticed—yet they are essential for safe, stable, and efficient relay mounting.

The HDS & ERS Series Relay Sockets stand out as a trusted choice for engineers, panel builders, and maintenance teams worldwide. In this blog, we will explore why these sockets have become the go-to option for industrial applications, their unique features, and how they can enhance your system’s performance.

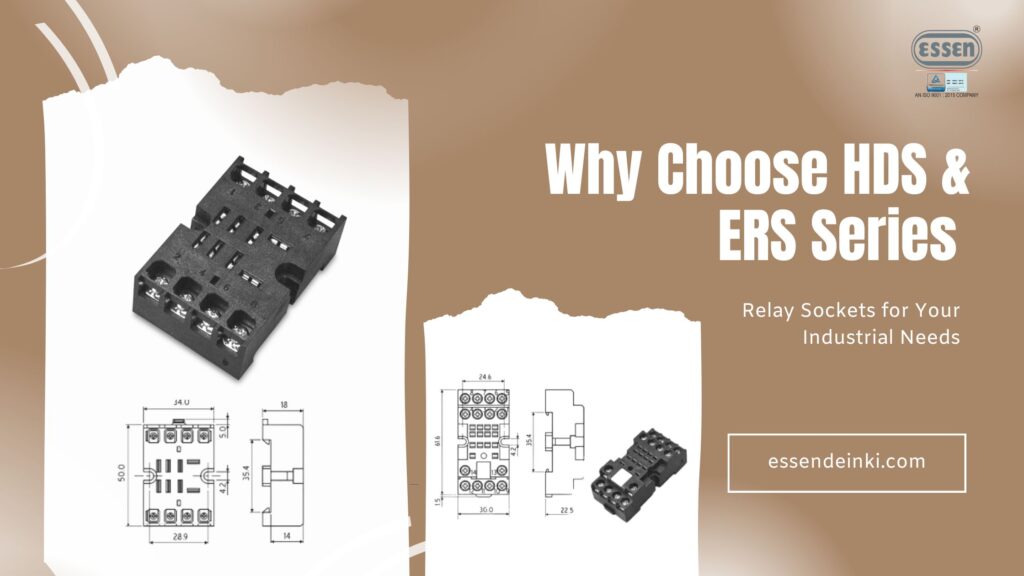

HDS & ERS Series Relay Sockets—A Quick Overview

The HDS and ERS series are purpose-built to provide secure, dependable connections for industrial relays. While both series share the same commitment to quality and performance, they are tailored for slightly different applications:

- HDS Series – Known for heavy-duty stability and robust construction, ideal for high-load industrial environments.

- ERS Series – Designed for efficiency and adaptability, offering versatile mounting and wiring configurations.

Both series embody the same core principles: durability, electrical safety, and ease of installation.

The Role of Industrial Relay Sockets in Automation

Before diving deeper into the specifics of the HDS and ERS series, let’s understand the importance of industrial relay sockets in an automation system.

Relay sockets serve as the interface between the electrical relay and the system wiring. They offer:

- Quick Relay Replacement – Technicians can swap out relays without rewiring, reducing downtime.

- Secure Mounting – Prevents loose connections that could lead to arcing or failure.

- Extended Relay Life – Proper socket design helps protect relays from vibration, heat, and electrical stress.

- Standardized Connections – Allows compatibility with a range of relay models.

In other words, without a reliable relay socket, even the best relay cannot perform to its full potential.

Why HDS & ERS Series Are Industry Favorites

1. Exceptional Build Quality

The HDS & ERS series are engineered with high-quality materials that withstand industrial stress. The sockets are resistant to heat, electrical wear, and mechanical vibration—ensuring stable operation even in harsh conditions.

2. Universal Compatibility

Both series are designed to fit standard industrial relays, making them suitable for a variety of brands and models. This compatibility reduces inventory complexity and simplifies procurement.

3. Safety as a Priority

The HDS & ERS series comply with global safety standards, featuring insulation materials and contact designs that prevent accidental electrical contact. This makes them ideal for environments where safety is non-negotiable.

HDS Series – Built for Heavy-Duty Applications

The HDS Series Relay Sockets are the heavyweights of the range. They are perfect for situations where relays must operate under high load currents, extended duty cycles, and challenging environmental conditions.

Key Features:

- Rugged construction for maximum mechanical stability.

- Screw-type terminals for secure, vibration-resistant connections.

- Heat-resistant materials for long operational life.

- Ideal for machinery control, conveyor systems, and motor starters.

With these features, the HDS series is a favorite for industries such as manufacturing, mining, and heavy equipment operations.

ERS Series – Versatility and Ease of Use

The ERS Series Relay Sockets are designed for flexibility, making them a popular choice for control panels and compact installations.

Key Features:

- Slim profile to save panel space.

- Push-in or screw-terminal options for quick wiring.

- DIN rail mounting for fast installation and replacement.

- Suitable for process control, building automation, and general industrial equipment.

The ERS series strikes a balance between performance and installation convenience, making them ideal for engineers who need adaptable solutions.

Advantages of Choosing HDS & ERS Series Relay Sockets

1. Reduced Downtime

The ability to quickly replace relays without rewiring means less downtime and higher productivity.

2. Cost Efficiency

Their durability reduces replacement frequency, saving both material and labor costs.

3. Simplified Maintenance

Standardized designs make it easier for technicians to stock spare parts and perform maintenance.

4. Enhanced Reliability

The robust design ensures stable performance in demanding environments, reducing the risk of electrical failures.

Applications Across Industries

The industrial relay sockets from the HDS and ERS series are used in a wide range of applications, including:

- Industrial Automation – PLC-controlled systems, conveyor belts, and robotic assembly lines.

- Power Distribution – Electrical panels, substations, and switchgear.

- Building Automation – HVAC systems, lighting control, and security systems.

- Transportation – Railway signaling, traffic control systems, and marine equipment.

Best Practices for Installing HDS & ERS Series Relay Sockets

To get the best performance from your sockets:

- Follow Manufacturer Guidelines—Ensure wiring, mounting, and torque specifications are followed.

- Use Correct Wire Sizes – Match the terminal capacity for optimal conductivity.

- Avoid Excessive Heat Exposure—Keep the sockets away from heat sources to prolong life.

- Regular Inspection—Periodically check for signs of wear, corrosion, or loosening.

Future-Proofing Your Electrical Systems

With technology advancing rapidly, having components that can adapt to new systems is crucial. The universal compatibility and long-term reliability of the HDS & ERS series mean they can easily integrate into future upgrades without costly redesigns.

Conclusion

Choosing the right industrial relay sockets is not just a technical decision—it’s a strategic one. The HDS & ERS Series Relay Sockets combine durability, compatibility, safety, and ease of installation, making them a wise investment for any industrial setup. Whether you’re running heavy-duty machinery or managing compact control panels, these sockets deliver the reliability your systems need.

In the world of industrial automation, small components often make the biggest difference. By choosing HDS & ERS series relay sockets, you ensure your operations remain efficient, safe, and ready for the challenges of tomorrow.