In industrial automation and electrical control systems, the efficiency of any machine depends heavily on how operators interact with it. Control panels may be the brain of operations, but push buttons and switches are the hands and senses that make everything work smoothly.

One of the most reliable and space-efficient solutions for panel builders is the PCB5 Series Twin-Push Button Switch.

In this guide, we’ll break down:

- Key features of the PCB5 Series

- Available types and ordering codes

- Installation and maintenance tips

- Why integrating Emergency Stop Switches is essential

What is the PCB5 Series Twin-Push Button?

The PCB5 Series is a dual-function push button switch that combines two actuators in one compact unit — typically:

- Green button (Start)

- Red button (Stop)

Instead of installing two separate 22.5mm push buttons, the PCB5 integrates both into a single housing, saving valuable panel space.

Key Features of the PCB5 Series

- Space-Saving Design

Panel space is always limited in MCC panels and distribution boards. The twin-push configuration reduces the number of panel cutouts, making it ideal for compact enclosures.

- Strong Plastic Mounting Bracket

Each unit comes with a durable plastic bracket that is:

- Lightweight

- Mechanically strong

- Designed for thousands of operations

- Ergonomic Operation

The buttons provide clear tactile feedback. Even in noisy factory environments, operators can feel the actuation and confirm the command instantly.

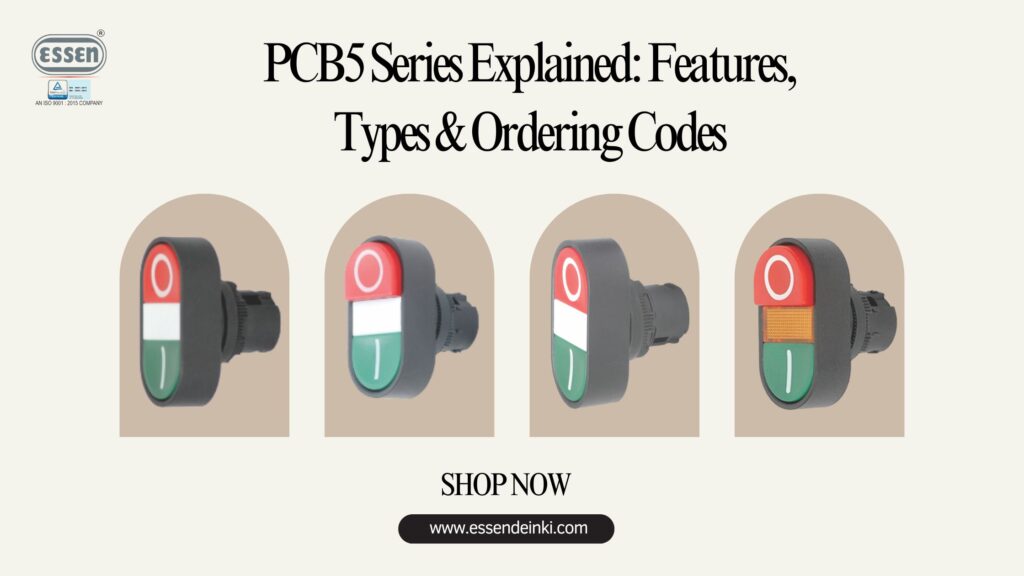

PCB5 Series Types & Ordering Codes

Understanding ordering codes helps during procurement and maintenance. Let’s explore the main variants.

PCB5-E8832 – Standard Flush Type

This is the base model of the series.

Configuration:

- Red flush button

- Green flush button

- Standard “O” (Stop) and “I” (Start) markings

Best for:

High-traffic areas where projecting buttons may snag clothing or equipment.

PCB5-EB842 – Projecting Red Type

In many industrial setups, stopping a machine quickly is more critical than starting it.

Configuration:

- Green flush button

- Red projecting button

Advantage:

The projecting red button can be located by touch alone. This improves response time during urgent situations.

PCB5-EBW 836 – Illuminated Flush Type (Amber Lens)

Modern panels require visual feedback.

Features:

- Two flush buttons

- Amber lens between them

Use Case:

The amber lens acts as a pilot light to indicate:

- Power ON

- Running status

- Fault condition

This reduces the need for a separate indicator lamp.

PCB5-EBW 846 – Illuminated Projecting Type

This is the most advanced model in the lineup.

Features:

- Projecting red button

- Green flush button

- Amber illuminated lens

Best for:

Complex machinery where both visual indication and quick tactile stop access are required.

Why Emergency Stop Switches Are Essential

While the PCB5 handles normal Start/Stop operations, it does not replace an Emergency Stop Switch.

A standard stop button performs a routine shutdown.

An Industrial Emergency Stop Switch:

- Cuts power instantly

- Locks in OFF position

- Requires manual reset

For machinery that poses any risk, an Emergency Stop Switch is mandatory under safety regulations.

As one of the trusted Emergency Stop Switch manufacturers in India, Essen Deinki emphasizes integrating proper safety components alongside operational controls.

Types of Emergency Stop Switches

Depending on your application, you may require:

Mushroom Head (Push-Pull)

Most common design. Easy to activate with palm pressure.

Key-Release Type

Prevents unauthorized machine restart.

Twist-to-Release

Ergonomic design that avoids accidental resets.

Safety Standards for Emergency Stop Buttons

When designing a panel with PCB5 switches, compliance is critical.

International standards such as ISO 13850 and IEC 60947-5-5 require:

- Red actuator

- Yellow background

- Positive opening operation

- Easy accessibility

Following these standards ensures compliance for domestic and export markets.

Installation Best Practices

To maximize performance and life:

Installation Tips

- Do not over-tighten the plastic bracket

- Use ferruled wire ends for secure connections

- Ensure proper alignment of illuminated lens models

Maintenance Checklist

Monthly

- Inspect for cracks or fading markings

Quarterly

- Test mechanical movement

- Check for dust or oil buildup

Yearly

- Retighten terminals if required

Regular inspection increases service life and prevents downtime.

Why Choose Essen Deinki?

When selecting industrial control components, reliability matters.

Essen Deinki is recognized among leading Emergency Stop Switch manufacturers in India, delivering:

- High-quality PCB5 Series switches

- Durable Industrial Emergency Stop Switches

- Strict quality testing

- Products built for harsh industrial environments

Our components are designed to withstand dust, vibration, heat, and continuous use.

Future of Control Panel Design

The industry is moving toward smart control panels integrated with PLC systems. Some systems now monitor push-button usage cycles for predictive maintenance.

However, no digital system can replace a hard-wired Industrial Emergency Stop Switch in critical situations.

Mechanical safety will always remain essential.

Conclusion

The PCB5 Series Twin-Push Button Switches offer:

Space efficiency

Reliable performance

Multiple configuration options

Integrated illumination choices

Whether you choose the standard PCB5-E8832 or the advanced PCB5-EBW 846, you are investing in dependable panel control.

But remember — operational control must always be paired with proper safety systems. Integrating certified Emergency Stop Switches ensures compliance, operator protection, and long-term reliability.

Visit our official PB5 Series page for detailed specifications and dimensional drawings.

Need a bulk quote or custom solution? Contact our team today.

Frequently Asked Questions

Q1: Can PCB5 Series be used outdoors?

It is primarily designed for indoor use. For outdoor applications, use an IP65/IP67 rated enclosure.

Q2: What is the purpose of the amber lens?

It provides visual indication such as machine status, power, or fault signals.

Q3: Why is the red button sometimes projecting?

For ergonomic safety. It allows faster stopping by touch.

Q4: Is an Emergency Stop Switch mandatory?

Yes. Any machine with injury risk must have a certified Emergency Stop Switch.

Q5: Are contact blocks replaceable?

Yes. The modular design allows contact block replacement without changing the entire unit.